Today, we want to explain the importance of abrasive cleaning to obtain an optimal coating.

It is more common than we would like customers to ask us to "save the shot blasting process" when it comes to coating metal parts. Generally, this event is due to the fact that the client seeks to reduce the cost of the coating as much as possible, and as you can imagine, these facts multiply in times of economic scarcity.

How much money do I save if I DO NOT shot blast the parts?

The answer to this question is very simple: YOU DON'T SAVE ANYTHING, YOU LOSE!

Obviously, if the process that involves abrasive cleaning of the parts is not carried out, the final unit price will decrease. It is because, not carrying out a production process shortens the times to achieve the final finish and as a consequence the final price decreases.

The key issue in this matter is the consequences of skipping the blasting process. For this reason, through this article we want to convey the importance of abrasive cleaning of metals.

Why the importance of abrasive cleaning and what are its functions

We can divide the blasting functions into two groups:

- On the one hand, and as its name suggests, abrasive cleaning is a cleaning process. More concretely, involves the cleaning of a metal surface by projection by continuous impacts of abrasives, which in the case of COVER These abrasives are angle steel shot. By impacting these particles on the metal surface at a pressure of 6Kg per cm2 (6 bar), calamine, rust, grease, previous coatings or any type of contaminant that may exist on the surface is eliminated.

Angular shot or sharp edge

- Second, another great feature of shot blasting is the adhesion. It is considered the most basic function of coatings, since, without a strong adhesion of the coating on the substrate, it will not reach a long useful life.

Therefore, the two great characteristics that a good surface cleaning using abrasives gives us are the cleaning of the surface itself and the adherence to it. Without these characteristics it is not possible to achieve a quality finish.

How is adhesion achieved by shot blasting?

Adhesion is a characteristic that can be achieved in three different ways:

- By chemical bond formed by the reaction between the substrate and the coating.

- Polar adhesion. The resin acts as a magnet attracting the opposite poles to the substrate.

- Mechanical adhesion it is achieved by shot blasting. The pressure at which the metallic particles impact on the surface generates a certain roughness in it, an anchoring pattern. This allows more contact points to be generated between surface and coating molecules, resulting in greater adhesion.

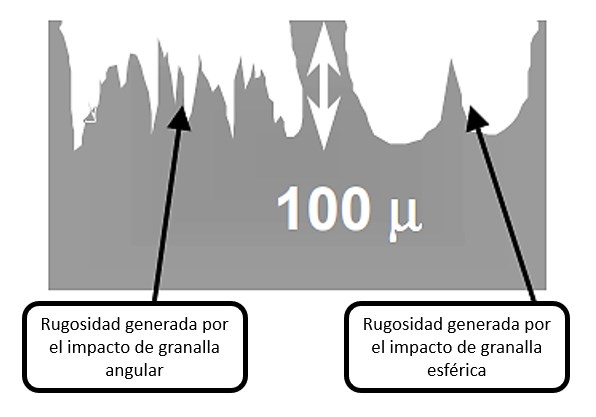

By blasting elements with sharp edges, an adequate anchoring profile is generated, obtaining a greater adhesion surface than spherical elements, which generate a poorer anchoring and therefore a very short useful life.

Where is the savings?

It is totally impossible to do a quality coating on a dirty or untreated surface. Without the proper measuring equipment, it is difficult to know if the final finish is what you want. It is because, visually, the coating may appear to be well done, however, under the protective layer we will find contaminants that will affect the metal we want to protect.

And it is that in this aspect, the data is devastating: 70% of the causes why a coating fails, are due to a poor surface preparation.

For these reasons, from our point of view, the way to "save money" with coatings is not based on skipping processes. On the contrary, it is based on meticulously carrying out each and every one of the necessary processes to ensure the highest quality of service and a long useful life for the materials.

We must take into account the reasons why we decide to coat materials. Among them, there is surely the need to provide an anticorrosive protection to the material, in which case we will want this protection to be durable over time.

The consequences of a surface with impurities will be noticeable over time, since under the protective layer, which should isolate the metal from the environment, the various contaminants will already have started to attack the metal.

If you found this article about the importance of abrasive cleaning interesting and you want to know more about corrosion, click here